The first thing you notice is the silence. Not the mournful hush of a train waiting in some dusty siding, but a bright, humming quiet — the sound of power moving without the usual roar, without diesel fumes, without the shudder of combustion. Somewhere far from the eucalyptus scrub and red soil of inland Australia, an enormous locomotive rolls forward on a test track, pulling a set of boxy freight wagons. There’s no smoke, no exhaust, just a faint whir and the soft rush of steel on steel. This is the world’s most powerful hydrogen locomotive, and it doesn’t belong to China. It belongs to China’s biggest rival — the United States — and it’s rewriting the script for what railways might sound like, smell like, and mean in a warming world.

Rivalry on the Rails: Why This Locomotive Matters Down Under

If you’re sitting in Sydney, Brisbane, Melbourne or a regional town where the freight line cuts straight through the edge of suburbia, it’s easy to think of international rail tech as something “over there.” Our trains are our trains; their trains are theirs. But rail has always been a quiet battleground of national ambition, and the race to build tomorrow’s clean, long‑range locomotives is quickly turning into one of the most important rivalries of the century.

China has spent years building the image of a rail superpower — high‑speed passenger services, sprawling freight networks, shimmering new stations. Yet in the background, the United States, often painted as car‑obsessed and highway‑bound, has just taken a dramatic leap forward: a hydrogen fuel cell locomotive powerful enough to haul serious freight, not just pose for glossy brochures. It’s not a sleek bullet train but a muscular, broad‑shouldered workhorse designed for the grimy, practical business of moving heavy stuff over long distances.

For Australians, who live on a continent that depends heavily on long‑haul freight and bulk exports, this is not a distant curiosity. This is a glimpse of what our inland rail corridors, mining supply chains, and port approaches could look — and feel — like in ten or twenty years. And it invites a quietly unsettling question: will we follow, lead, or get left rattling along behind on yesterday’s technology?

The Smell of Tomorrow: Inside a Hydrogen Locomotive

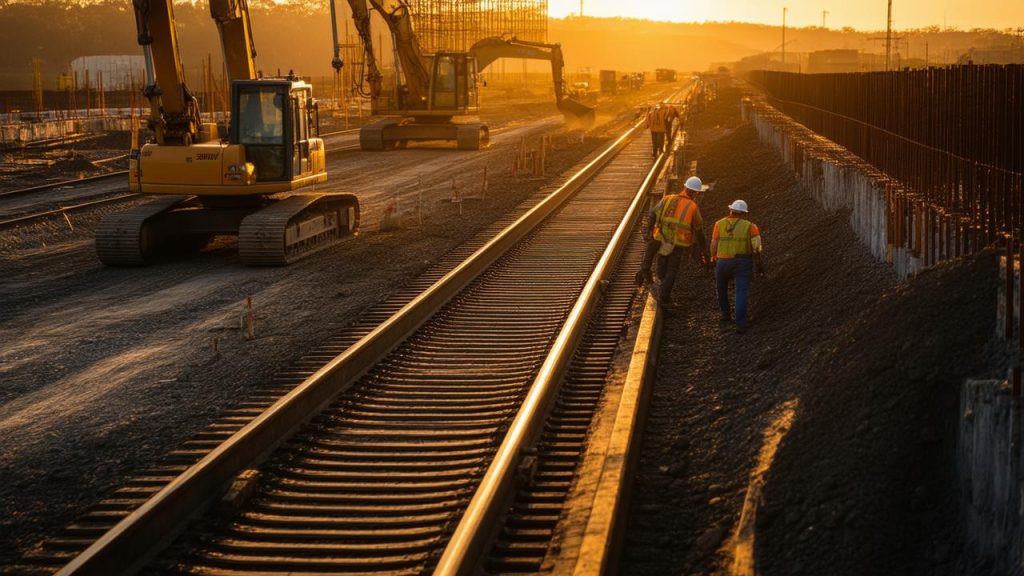

Imagine standing beside a standard diesel locomotive in the Pilbara at dawn. The air carries the sticky tang of exhaust, a metallic taste mixed with desert dust. The engine coughs into life with a brutal clatter, sending a tremor through the ballast beneath your boots. That’s the soundtrack of Australia’s resource economy, the pulse of iron ore and grain and intermodal freight heading to distant ports.

Now swap that scene for a hydrogen locomotive. You’re on a siding in California, or a testing yard somewhere in the American Midwest. The locomotive ahead of you is enormous, painted in experimental colours, still wearing the cautious, temporary markings of a prototype. A low electric hum spreads into the air, like a distant substation, and somewhere deep inside, fuel cells begin their quiet magic: hydrogen meeting oxygen in a carefully managed reaction, producing electricity and nothing more dangerous than water vapour and warmth.

The smell of diesel is gone. In its place, there’s only cold morning air and the faint wetness of condensation drifting off the undercarriage. A set of heavy wagons lurches into motion, not with the usual roar, but with a silky surge of torque — electric motors converting hydrogen’s hidden energy into movement. It feels almost eerie. You can hear voices clearly over the sound of motion. You can smell the nearby grass, the dust, the hot grease on couplings. Everything you used to associate with trains is still there — except the pollution.

What makes this particular locomotive headline‑worthy is its sheer grunt. Hydrogen trains already run in parts of Europe, mostly as light regional passenger sets. This American machine pushes into a different category: high‑horsepower freight, the domain where diesel’s dominance has been almost absolute. Breaking that barrier is like watching the first electric ute roll confidently up a steep, red‑dirt station track while towing a full trailer. It means “clean” doesn’t have to mean “delicate.”

Horsepower, Range and Reality

Under the skin, the locomotive is a rolling chemistry experiment and a battery lab combined — tanks of compressed hydrogen, stacks of fuel cells feeding power to electric traction motors, and a hefty onboard energy storage system to handle surges and regenerative braking. The result is a machine capable of rivaling, and potentially beating, conventional diesel in both pulling power and efficiency across a full working day.

That’s the bit that should make freight operators — and policymakers in Canberra — sit forward in their seats. This is no longer just a climate story. It’s a story about cost, resilience, and who controls the next generation of industrial hardware.

China, America, and the Quiet Race for Rail Influence

Step back from the technical details and you see a bigger tension playing out. China has led in high‑speed passenger rail, dazzling the world with networks that knitted together cities at astonishing speed. The United States, by contrast, leaned heavily on its massive freight system — long trains, heavy loads, low‑profile hardware that never makes Instagram but keeps supermarkets stocked and factories running.

Now the rivalry has switched tracks to climate technology. China has been pushing electric and hybrid locomotives, experimenting with hydrogen in a more cautious way, often tied to state‑driven projects. The US, powered by a strange alliance of rail operators, tech firms and state agencies, has begun aiming straight for the heart of its own network: decarbonising the locomotives that drag endless lines of containers and bulk commodities across the continent.

A record‑setting hydrogen locomotive is more than an engineering trophy; it’s a statement. It says: “We intend to own this part of the future.” And in a century where clean tech and infrastructure are increasingly tangled with geopolitics, that message doesn’t stop at the Pacific.

Australia, wedged economically between Chinese demand and American security guarantees, suddenly finds its rail future sitting on a strategic fault line. Whose technologies do we adopt? Whose standards do we align with? Which supply chains — for hydrogen, for fuel cells, for control systems — do we trust?

What This Means in an Australian Rail Yard

Picture a yard in Western Sydney in 2035. A long‑distance freight service rolls in from Melbourne, the locomotive slowing under a lattice of gantries and old sodium lights. Around you, utes idle, forklifts beep, and planes from the nearby airport trace their glare across the low clouds. But the locomotive gliding past is different. No diesel growl. No smoky aftertaste at the back of your throat. Just the soft whine of electric traction and the hiss of air brakes.

On its livery is not a Chinese or American flag, but the badge of an Australian operator — who has had to choose whose hydrogen tech to license, whose maintenance standards to follow, whose training manuals their apprentices are memorising. The decision, made years earlier in a boardroom and later nudged by ministers, has woven another set of threads into the fabric of our economic alliances.

Australia’s Long Distances and the Lure of Hydrogen

There is a reason rail buffs and energy analysts get equally animated about hydrogen trains in an Australian context. Our geography is both a curse and a gift. Catenary wires — those familiar overhead electric lines — make perfect sense between dense European cities or along busy Asian corridors. Out here, threading high‑voltage wires across thousands of kilometres of sparsely populated country, through floodplains and heat‑warped deserts, quickly becomes an eye‑watering expense.

Hydrogen offers a different logic: bring the energy with you. Instead of investing everywhere in poles, wires and substations, you concentrate infrastructure in hubs — hydrogen production, compression, storage — then feed your locomotives like you’d refuel a truck, only cleaner.

For a country already rich in solar and wind, the prospect glows with possibility. Daytime sun could be turned into hydrogen at scale in the interior, then piped or trucked to refuelling depots along the main freight arteries. A hydrogen train rolling out of Port Hedland or Kwinana could, in theory, be hauling ore powered by the same sunlight that bleaches the surrounding spinifex.

But “in theory” is doing a lot of work. Hydrogen is notoriously tricky to produce cheaply, store safely, and move without losing too much energy along the way. Locomotives like the record‑setting American prototype are as much testbeds for those supporting systems — valves, compressors, tanks, logistics — as they are for motors and fuel cells. The hardware on the tracks won’t mean much if the hardware at the depots and ports can’t keep up.

Where Australia Is Already Experimenting

Across the country, small signals are blinking green. Pilbara mining giants are trialling alternative fuels and hybrid systems for their massive rail operations. State governments are flirting with hydrogen buses and exploring zero‑emissions options for regional passenger lines. University labs and CSIRO teams quietly tinker with membranes, catalysts and storage materials, trying to shave costs and tame the physics.

Yet we are still in the “patchwork intentions” stage rather than a clear, confident national push. While the US and China wrestle for bragging rights over the world’s most powerful hydrogen locomotive, Australia is standing on the platform with a ticket in hand, deciding which train to board.

➡️ The streak-free window-cleaning method that still works flawlessly even in freezing temperatures

➡️ The quick and effective method to restore your TV screen to like-new condition

➡️ Thousands of passengers stranded in USA as Delta, American, JetBlue, Spirit and others cancel 470 and delay 4,946 flights, disrupting Atlanta, Chicago, New York, Los Angeles, Dallas, Miami, Orlando, Boston, Detroit, Fort Lauderdale and more

➡️ The sleep pattern that predicts alzheimer’s risk 15 years before symptoms

➡️ These zodiac signs are destined for major prosperity in 2026, according to astrological forecasts

➡️ The RSPCA urges anyone with robins in their garden to put out this simple kitchen staple to help birds cope right now

➡️ The RSPCA urges anyone with robins in their garden to put out this simple kitchen staple today

Numbers on the Line: Comparing Old and New Power

It’s easy to get lost in the romance of clean, silent trains, but railways are unforgivingly practical. Operators care less about poetry and more about numbers: tonnage, gradients, fuel bills, maintenance windows. To bring this down to Earth — or rather, down to track level — here’s how hydrogen locomotives stack up conceptually against the diesel workhorses that dominate Australian freight today:

| Feature | Typical Diesel Freight Loco | Next‑Gen Hydrogen Freight Loco |

|---|---|---|

| Primary energy source | Diesel fuel (fossil) | Hydrogen (can be renewable) |

| Local emissions at trackside | CO₂, NOx, particulates | Mainly water vapour |

| Noise profile | Loud engine noise, idling rumble | Quieter electric hum |

| Refuelling / turnaround | Established diesel network | New hydrogen infrastructure needed |

| Strategic upside for Australia | Locked into imported fossil fuels | Potential to use domestic renewable resources |

For communities living along busy freight corridors — think the outer suburbs of Adelaide, the Hunter, or the fringes of Perth — those differences add up to more than a spreadsheet entry. It’s the soundscape of your evening, the air your kids breathe in the backyard, the way your house shakes when a heavy consist crawls past in the small hours.

Will Australia Watch, Buy, or Build?

So where does this leave us, as China and its biggest rival duel over tomorrow’s trains? Standing in a curious in‑between space.

We have the raw ingredients for a hydrogen‑powered rail revolution: world‑class renewables, a powerful mining and freight sector hungry for efficiency, research institutions that know their way around complex energy systems, and a growing national conversation about decarbonising heavy transport. We also have deep trade ties with China, a security alliance with the United States, and a habit of importing big, complex machines rather than building them from the ground up.

The arrival of a record‑breaking hydrogen locomotive overseas is a reminder that we don’t have forever to sit on the fence. As standards harden, patents pile up, and supply chains get locked in, it becomes harder for latecomers to negotiate the best deals or carve out their own niche. If Australia wants to shape the smell and sound of its future trains — from the Pilbara’s ore lines to the inland freight spines linking capitals — the time to choose our direction is uncomfortably close.

In the end, the story playing out on a distant test track is not just about China, or America, or engineering prowess. It’s about the kind of country we want to be when the last diesel locomotive is finally retired to a museum siding and kids press their faces to the glass, wondering what that greasy, rattling monster must have sounded like in its prime.

By then, perhaps, they’ll be used to something different: trains that slip past with little more than a whisper, leaving only a fading echo and a brief, cool breath of air in their wake — and the knowledge that in a world of fierce rivals and fast‑moving technology, Australia found its own way onto the clean, bright rails of tomorrow.

Frequently Asked Questions

What is a hydrogen locomotive, in simple terms?

A hydrogen locomotive uses hydrogen fuel cells and onboard energy storage to power electric motors instead of burning diesel. Hydrogen reacts with oxygen in the fuel cells to create electricity, and the main by‑product is water vapour.

Why is the world’s most powerful hydrogen locomotive such a big deal?

Because it moves hydrogen trains from “light passenger novelty” into serious freight territory. High‑power freight locomotives are the backbone of bulk transport. Showing that hydrogen can compete here proves it’s a realistic replacement for diesel, not just a green experiment.

How could hydrogen trains benefit Australia specifically?

Australia has long rail distances, huge freight tasks and excellent renewable energy resources. Hydrogen trains could reduce emissions, noise and air pollution along busy freight corridors while using locally produced, renewable hydrogen instead of imported diesel.

Are hydrogen trains safer or more dangerous than diesel trains?

They’re different, rather than simply safer or riskier. Hydrogen is highly flammable, but so is diesel. Modern hydrogen systems rely on strict engineering, ventilation and sensor standards. With good design, the safety profile can be comparable to or better than current diesel operations.

When might we see hydrogen freight trains operating in Australia?

Timelines depend on investment and policy. Trials could realistically appear over the next decade, particularly in mining regions or on key freight corridors. Widespread adoption would likely take longer, as operators test performance, build refuelling networks and replace older fleets.