The wind off the North Sea smells like cold iron and rain the morning the first coils of electric steel roll off the line in northern France. Outside, the sky is the colour of wet concrete; inside, the air hums with the low, steady growl of machinery and the soft crackle of electricity. A crane glides past like a giant yellow seabird, lifting a glowing ribbon of metal that will, one day soon, become the beating heart of an electric motor.

On the surface, this is just another factory in Europe’s industrial belt – 500 million euros sunk into a sprawling complex of sheds, furnaces and control rooms. But the people moving quietly along its gantries and corridors know they’re standing at a fault line: between the age of oil and the age of electrons. By 2032, they’re betting this place will be feeding a slice of a €57 billion global electric steel market. And whether you’re in a Melbourne townhouse, a Perth mine site or a solar-powered farm on the Darling Downs, the ripples from this French factory will reach you.

Steel That Carries Electricity, Not Just Holds Up Bridges

When most of us think of steel, we picture girders, pipelines, shipping containers – the bones of our built world. Electric steel is different. It’s the quiet, hidden muscle in things that move because of magnets: EV motors, wind turbines, transformers perched on power poles, the humming substations we pass on the school run.

Electric steel – often called electrical steel or silicon steel – is engineered to do something very specific: guide and tame magnetic fields with minimal energy loss. It’s made by tweaking the recipe of ordinary steel, slipping in silicon and other elements, then processing it into thin sheets with carefully controlled crystal structures. When stacked together, those sheets form the cores of motors and transformers.

Every time we plug in an EV, start an induction motor at a mine, or send solar power down a transmission line, this kind of steel is quietly at work, channelling magnetism, shaving off inefficiencies measured in fractions of a percent. But scale that across millions of motors, thousands of turbines, and an entire electrified economy, and those tiny gains translate into national energy savings – and serious money.

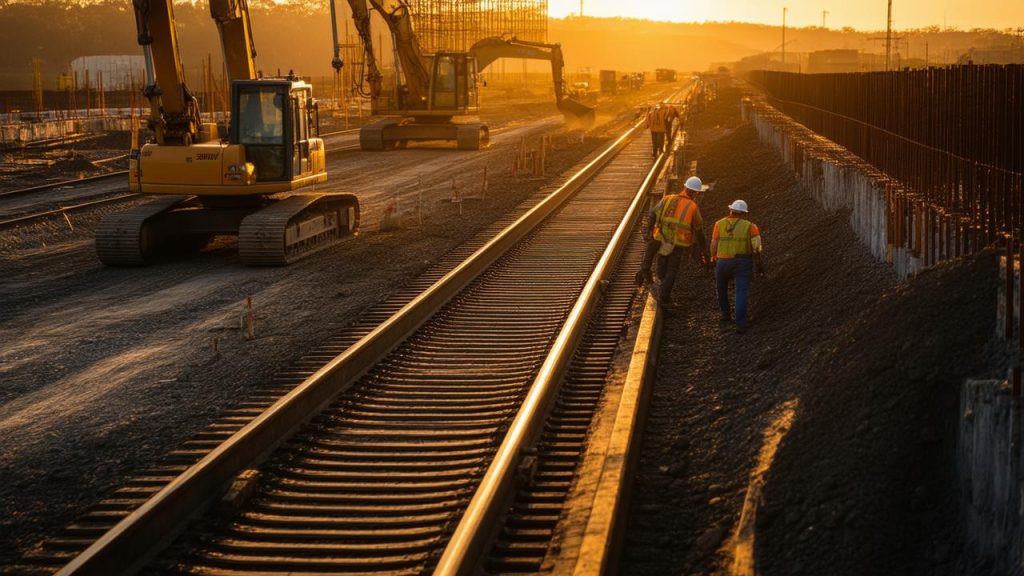

A Factory in the Mist, A Market on Fire

Step inside the French plant’s control room and it feels more like a regional air traffic control centre than an old-world steel mill. Operators sit behind glass, hands around mugs of black coffee, eyes on screens filled with rolling graphs and thermal maps. On the far wall, a real-time dashboard tracks production: tonnage, quality metrics, energy use per coil – and, less visibly, the arc of a global market impatient for more.

Industry analysts now expect the electric steel market to reach about €57 billion by 2032, driven by three converging forces: the relentless rise of electric vehicles, the build-out of renewable energy, and the modernisation of ageing grids. Every one of those pillars leans heavily on specialised steel.

The French factory is designed as a pure bet on that future. Half a billion euros is not a casual gamble. It’s a statement the way a new mine in the Pilbara is a statement: we expect long-term demand, and we’re building ahead of it. What they’re producing here isn’t a finished car or a turbine blade – it’s the upstream material that makes those downstream dreams work.

The Quiet Thread Tying France to Australia

From an Australian distance, a factory town in northern France can seem abstract, something tucked between vineyards and motorways on the far side of the world. But the supply chains it feeds are already braided into our lives.

Imagine a bright-orange electric ute crunching down a gravel track on a Queensland cattle station, its motor whisper-quiet apart from the crunch of tyres and the call of galahs overhead. Inside that motor’s stator and rotor are cores made from electrical steel, imported in sheets or pre-cut laminations. The ute’s battery might be filled with Australian lithium, but the magnetics inside – those sheets born from European or Asian mills – are just as crucial for every turn of the wheels.

Or picture a row of transformers along a dusty road out past Kalgoorlie, stepping down high-voltage power from a solar farm to feed into a remote community. Each transformer core is built from hundreds of slender, precisely aligned strips of electric steel. The better that steel is – the purer, the more finely tuned the grain – the less energy is lost as heat. In Australia’s long, stretched-out grid, where every kilometre matters, those efficiency gains are pure gold.

We tend to see the shiny end products: the rooftop panels, the battery packs, the sleek EVs charging at a servo off the Hume. But somewhere behind all that are places like this French factory, where molten metal meets human patience and process engineering. The choices they make – on quality, volume, and who they ship to – ripple down into the cost and performance of technology we’re trying to roll out across a continent.

Why This Matters for Australia’s Energy Shift

Australia is racing to rewire itself. Coal plants are retiring. Rooftop solar is spreading like lantana, only welcome this time. Wind farms march across ridges from the Wheatbelt to the Snowy Valleys. Mines are electrifying, ports are retooling, and regional towns are dreaming up microgrids that keep the lights on when storms take down the big lines.

Underneath all that is a physical reality we don’t talk about much: the hardware needed to move electrons, not diesel. More electric motors. More transformers. More high-efficiency generators. More transmission. All of it, in some way, is hungry for electric steel.

For Australians, the northern French factory is a bellwether: proof that serious capital is mobilising around a new industrial backbone. While we argue over planning approvals for wind turbines or high-voltage lines, companies elsewhere are quietly building the guts of the future grid – and locking in markets.

Australia has a choice. We can remain, primarily, the exporter of what goes into steel – iron ore, coal (for now), and, increasingly, renewable energy to power the smelters of others. Or we can decide that supplying this kind of speciality material is part of our own manufacturing story again.

From Ore to Opportunity

It isn’t lost on anyone in the global industry that the ore feeding many of the world’s steel plants comes from Australian soil. Vast open pits in Western Australia’s Pilbara and other regions ship mountains of iron ore to Asia and beyond. Those cargoes are the skeletons of future transformers, motors and turbines.

Yet turning ore into electric steel isn’t just a matter of firing up a blast furnace. It needs tight control, precise alloying, and often low-emissions power to be competitive in a decarbonising world. That’s a space where Australia, rich in both resources and renewable energy potential, could place its own bets.

A Market in Numbers – And in Texture

Data analysts translate all of this into tables and forecasts. On their screens, the next decade unfolds as neat curves and steadily climbing bars. On the factory floor in France, those numbers smell like oil and hot metal.

| Year | Estimated Global Electric Steel Market | Key Demand Drivers |

|---|---|---|

| 2024 | ~€30–35 billion | Early EV adoption, grid upgrades, renewable additions |

| 2028 | ~€45–50 billion | Mass-market EVs, wind & solar scaling, data centre power needs |

| 2032 (forecast) | ~€57 billion+ | Electrified industry, heavy transport, mature renewable grids |

By 2032, when analysts expect that €57 billion figure to be reached, Australians could be living in a very different energy landscape. The petrol bowsers in suburban servo forecourts might share space with high-speed chargers as ordinary as today’s air pumps. Mines across the outback could be running fleets of electric haul trucks, their motors roaring silently under the desert stars.

The hum we hear on a hot day – transformers, air-conditioning compressors, trains sliding into underground stations – will be the audible evidence of countless tonnes of electric steel doing their job. In that soundscape, the French factory’s contribution will be indistinguishable from similar plants in Japan, Korea, India, or perhaps one day, northern Australia.

Resilience in a Warming, Electrifying World

There’s another dimension to this story that matters in a fire-prone, storm-battered country stitched together by transmission lines. As climate change sharpens, grids need to be tougher. They must restart faster after blackouts, move power from where the sun is shining to where the skies are dark, and cope with surging EV charging after a scorcher of a day.

Better electric steel is not a silver bullet, but it’s a quiet upgrade. More efficient transformer cores mean less heat stress on equipment during peak loads. High-grade motor steel can allow more compact, robust designs for everything from rail locomotives to pumps in remote outstations. When we talk about “grid resilience,” we rarely picture the thin, carefully oriented sheets of metal at the core of these devices – but they’re there, bearing the load.

➡️ The streak-free window-cleaning method that still works flawlessly even in freezing temperatures

➡️ The quick and effective method to restore your TV screen to like-new condition

➡️ Thousands of passengers stranded in USA as Delta, American, JetBlue, Spirit and others cancel 470 and delay 4,946 flights, disrupting Atlanta, Chicago, New York, Los Angeles, Dallas, Miami, Orlando, Boston, Detroit, Fort Lauderdale and more

➡️ The sleep pattern that predicts alzheimer’s risk 15 years before symptoms

➡️ These zodiac signs are destined for major prosperity in 2026, according to astrological forecasts

➡️ The RSPCA urges anyone with robins in their garden to put out this simple kitchen staple to help birds cope right now

➡️ The RSPCA urges anyone with robins in their garden to put out this simple kitchen staple today

What This Factory Signals About the Next Industrial Age

Look again at that 500 million euro price tag. It signals that the next industrial age won’t just be about apps and software. It will be anchored in matter: metals that bend, conduct, and endure. It will be about who controls the know-how to make a specific kind of steel at scale, with low emissions, at high quality, reliable enough to go into safety-critical systems.

From an Australian perspective, the story of this northern French plant invites a harder question: where do we want to sit in that value chain? Are we content to remain, mostly, a quarry and a solar farm – exporting ore and raw electrons, importing high-value components? Or do we want some of the next generation of mills, laminators and finishing plants humming beside our own coasts?

Imagining an Australian Echo

It’s not hard to imagine a similar sight somewhere along the Hunter, in Whyalla, or near Kwinana: a low-slung factory by the water, cranes arching over ships, coils of electric steel stacked like giant metallic pastries under a sea breeze. Inside, technicians watch the grain structure of steel as carefully as baristas watch the crema on an espresso.

In that version of the future, Australian iron ore might travel only a short distance to become electric steel, powered by solar, wind and perhaps green hydrogen. Local companies could feed the next waves of EV manufacturing in Asia, supply transformers to Pacific neighbours, and build the strong magnetic cores for a new generation of offshore wind turbines, even if those turbines stand in foreign waters.

The French factory, then, is not just a European story. It’s a mirror held up across hemispheres, asking: if they can stake half a billion euros on a more electric world, what are we willing to stake from here?

Living With the Consequences of Our Bets

Back in northern France, as twilight blurs the horizon, the factory lights come into sharper focus. Trucks roll in, trains pull out. Somewhere on the other side of the globe, the last light fades behind the Indian Ocean as Australia settles into another evening of air-conditioners and induction cooktops, streaming movies and late-night laundry – all powered by an increasingly mixed grid of coal, sun, wind and water.

The choices we make in the coming years – about where we build factories, what we demand from our energy system, how far we’re willing to stretch supply chains – will decide whether the promise of a €57 billion electric steel market by 2032 is simply another line on a global balance sheet, or part of a deeper reweaving of how countries like ours participate in the physical making of the future.

For now, the French plant hums on, turning liquid fire into quiet metal, each coil a possible future: the motor in a bus in Brisbane, the transformer on a pole in Hobart, the generator in a wind turbine off the coast of Scotland. It is one factory among many, in one region among many. But in rooms where serious money runs the numbers on climate, energy, and industry, it stands as a sign that the age of electricity is not just about cleaner power.

It’s also about the humble, heavy, beautifully engineered materials that make those electrons dance.

Frequently Asked Questions

What is electric steel, in simple terms?

Electric steel is a special type of steel designed to guide magnetic fields efficiently. It’s used in motors, generators and transformers – the hardware that makes modern electrical systems work with minimal energy loss.

Why is this French factory important to Australians?

Because it will help supply the global demand for the components inside EVs, renewable energy projects and grid equipment that Australia is increasingly relying on. Changes in this upstream supply affect prices, availability and performance of technology we import.

How does a €57 billion market by 2032 affect Australia?

It signals strong long-term demand for electric steel, creating opportunities for Australian raw material exporters and, potentially, for local manufacturing if we choose to invest in value-added processing.

Could Australia build its own electric steel plants?

Yes, in principle. We have the iron ore, growing renewable energy capacity and industrial experience. It would require major investment, policy certainty and a clear strategy to compete on quality and low emissions.

What does this mean for everyday Australians?

Over time, it influences the cost and reliability of EVs, household appliances, electricity networks and renewable projects. Better and more abundant electric steel can help make our energy system cleaner, more efficient and more resilient.